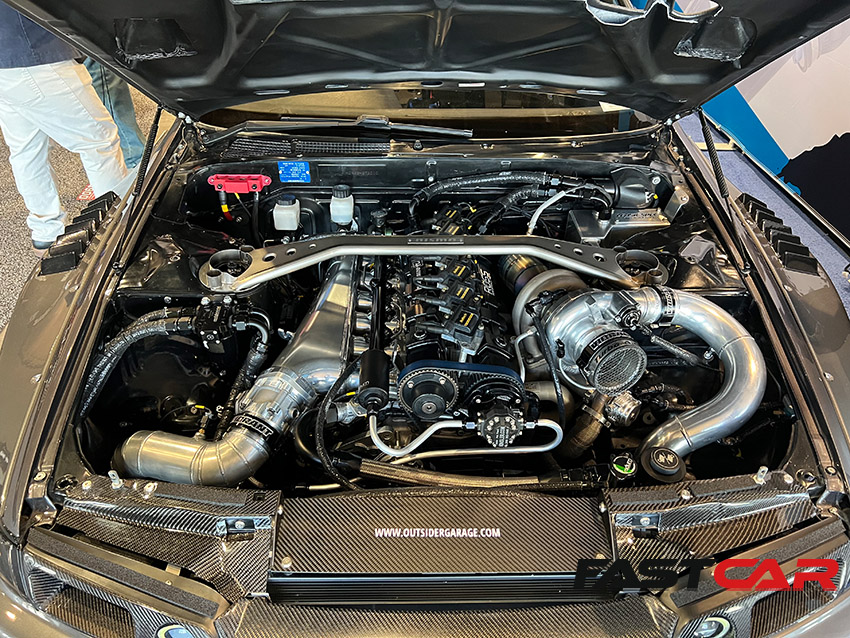

Cars Engine Tuning

Car Engine Tuning is a service we provide, It depends on the Car Manufacturer and model, also the payment method.

- ECU remapping. Modifying a car's engine control unit (ECU) helps to improve power and performance. ...

- Chip tuning. Replacing a car's stock chip with an aftermarket chip can improve the air/fuel ratio, ignition timing, and other engine parameters. ...

- Air intake upgrade. ...

- Turbocharging/supercharging

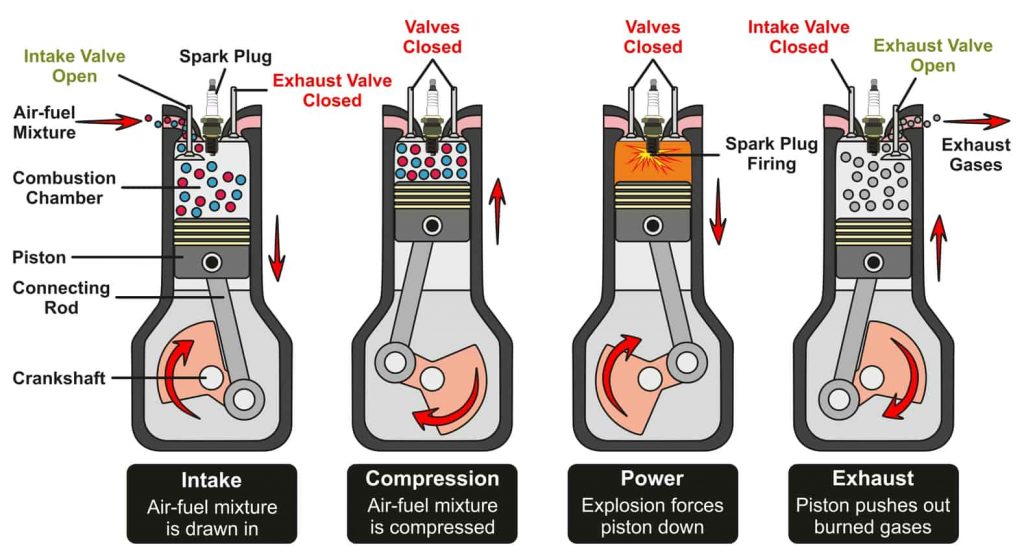

Intake

The intake stroke is where the piston lowers inside the cylinder. As it is lowering, the intake valve is simultaneously opening. The lowering of the piston (with the exhaust valve closed) creates a vacuum and sucks in the air through the intake valve. Prior to the intake valve is a fuel injector (for port injected cars at least. Some cars have direct injected engines with the injector in the combustion chamber). This fuel injector will vary the amount of fuel introduced based on the amount of air being fed into the cylinder.

Compression

During the compression stroke, both the intake and exhaust valves are closed (many engines have more than 2 but the point is all valves are closed or near closed during this stroke) and the crankshaft is moving upward compressing the air fuel mixture in the combustion chamber.

Power

Next up is the power or combustion stroke. When the piston reaches somewhere near the top, or top dead center (TDC), the spark plug ignites the compressed air fuel mix resulting in combustion. This forces the piston downward which forces the crankshaft to continue turning (in in turn, turns whatever it is connected to – like your transmission which is connected to your wheels).

Exhaust

That spent gas has to go somewhere. Enter – exhaust stroke. When the piston reaches somewhere near the bottom the exhaust valve opens. The intake valve stays closed and the piston goes back up. This forces the used mixture out of the exhaust valve and through the rest of the exhaust.

Not shown above is how these are all connected. Here is a gif to help visual the combustion cycle in action.

This also shows us how the crankshaft is connected to a timing belt or chain. This belt is connected to a cam gear which is connected to the camshaft(s). The camshaft has lobes which force valves open. These lobes are positioned on the camshaft at specific angles with a specific relationship to the position of the crankshaft. Note that the crank goes down and up twice for each time the valve opens (or each rotation of the camshaft). On any four stroke engine, the gear ratio between the camshaft and crankshaft will always be 2:1.

Our example engine above is a dual overhead cam (DOHC) inline four cylinder engine with four valves per cylinder. Some engines like the GM LS have only one camshaft and two valves per cylinder. Some have four or more cams with 5 or more valves per cylinder (there have been engines with more than 5 but that seems to be more trouble than it’s worth). There are also different layouts for an engine which position the cylinders not in a row but in a V shape, a flat or horizontally opposed layout, or even a W layout. While these different layouts or number of cams or valves can offer different opportunities or limitations, when it comes to tuning, they all require the same demands; fuel, air, and spark.

Now that you’ve got an understanding of the combustion cycle let’s get into the nitty gritty of what controls it; the ECU.

ECU Tuning

On modern, electronic fuel injected cars, there is an Engine Control Unit (ECU) which controls the engine. This ECU gathers data from various sensors around the engine. This sensor data is interpreted and then used to send signals to various outputs like fuel injectors and ignition coils. Based on the signal inputs, the ECU determines the amount of fuel to inject and when to ignite the spark plug.

There are also aftermarket ECUs or a “standalone” ECU which will completely eliminate and replace your factory ECU. The benefit here is infinite adjustability, control, and lots of room for custom features. If using a standalone ECU, you will need to configure all sensor data before you start tuning the engine. However, most goals can be achieved by using the factory ECU. The benefit with the stock ECU is that the architecture is already in place. You simply need the software to make the necessary tuning changes and the hardware to get those changes onto the ECU.

The ECU involves several different “tables”. Tables are comprised of different cells which contain values specific to certain inputs. These inputs are typically arranged with their minimum and maximum values along an X and Y axis. Changing these values is the root of ECU tuning for your engine.

Some ECUs have thousands of these tables. When tuning a car, it’s not uncommon to modify hundreds of these table to reach the desired outcome. Let’s go over some of the more important tables.

Fuel Mixture

No combustion engine can run without fuel and air. In order to tune your car, you’ll need a thorough understanding of their relationship and how your engine uses them. There are different strategies used to manage this mixture. Here, we’ll focus on a speed density tuning strategy which uses a Manifold Absolute Pressure sensor to measure incoming airflow. Vehicles that use a MAF sensor will be a little different but the overall concept is similar.

Below is one of the most important tables when it comes to tuning your car’s engine. This table will determine the amount of fuel injected based on a given airflow and RPM.